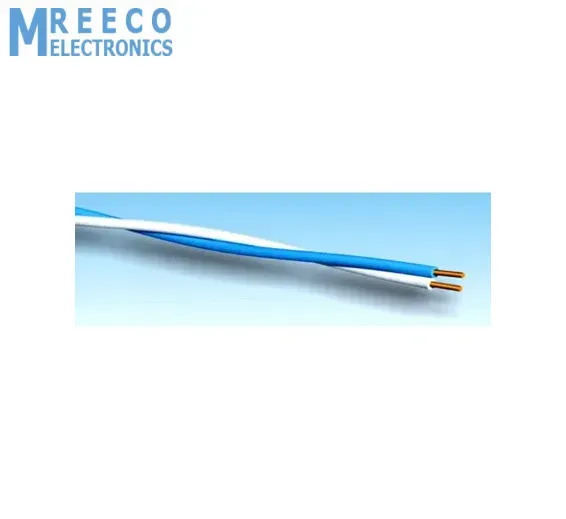

1 Meter 10pcs Hard Jumper Wires 100cm spiral wrap wires 10 core cable

SKU: 637718958828835258

Hard Jumper wires have connector pins at both ends, allowing them to be used to connect two points to each other without soldering. These hook up wires are mostly used with breadboards and other prototyping tools/ boards to make it easy to customize a circuit according to your requirements.

A breadboard wire establishes an electrical connection between two points in a circuit. Jumper wires can be used to modify a circuit or to detect problems in a circuit. These are specifically male to male connection wires.

It is tougher than a stranded conductor, but rigid and less flexible than a stranded conductor. Solid conductors are more likely to break if subjected to frequent flexing than stranded conductors.To help you visualize its rigidness, it is more flexible than a solid conductor, but less durable.

Pin to Pin hard wires are sometimes used to bypass a portion of the circuit (such as a stretch of wire or a switch) that DOES NOT contain a resistor and is suspected to be bad. In other words, you can use a jumper wire to provide a direct path for current to pass through.

Specifications:

- Pin to Pin configuration

- Available in minimum 1 meter (100cm) lengths and longer

- Individual cores or wires can be separated for multi-purpose use

- Each core in cable is individual separate color!

- 10 thin wires packaged in a spiral cable wrap

- Cut the wire to the length you need, using a wire-cutting tool.If you need, say, a 1-inch jumper wire, cut a length of wire that is at least 1-3/4 inches long, so you leave room to strip some insulation off each end. It’s better to cut a longer length of wire and trim it down if you need to than to cut a shorter length of wire and find that it’s too short for your circuit.

- Strip off about 1/4- to 1/3-inch of insulation from each end.If you use a gauged wire stripper, follow these steps: If you use a generic wire stripper, follow these steps:

- Dial the gauge to 20 or 22 (depending on what gauge your wire is) or locate the notch that is labeled 20 or 22.

- With the jaws of the wire stripper open, place the wire in the appropriate notch of the wire stripper, so that roughly ¼- to 1/3-inch of the wire extends past the wire stripper.

- Firmly grip the wire stripper — as if you’re trying to cut through the wire — while twisting and pulling the wire through the stripping tool. The insulation should come off but the wire should remain intact.

- Place the end of the wire into the cutting blades of the wire stripper, so that roughly 1/4- to 1/3-inch of the wire extends past the wire stripper.

- Grip the wire stripper just enough to begin cutting through the insulation. (If you grip it too tightly, you will nick or cut through the wire. If you don’t grip it tightly enough, you won’t cut through the insulation at all.)

- Release your grip on the wire stripper, rotate the wire a quarter turn, and then grip the wire stripper again with just enough pressure to begin cutting through the insulation.

- Rotate and repeat steps b and c two or three more times, until you have nicked the insulation all the way around the wire.

- Grip the wire stripper — but not too tightly — around the nicked insulation while pulling on the other end of the wire to force the insulation off.

With a little practice, you’ll become an expert in making jumper wires!